Our manufacturing plant is equipped with cutting-edge technology and rigorous quality control at every step. From sourcing ingredients to final packaging, we ensure the highest standards of safety, purity, and effectiveness, delivering nutraceutical and Ayurvedic products you can trust.

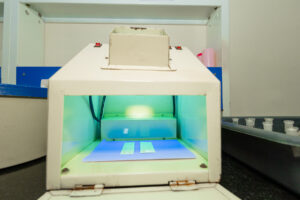

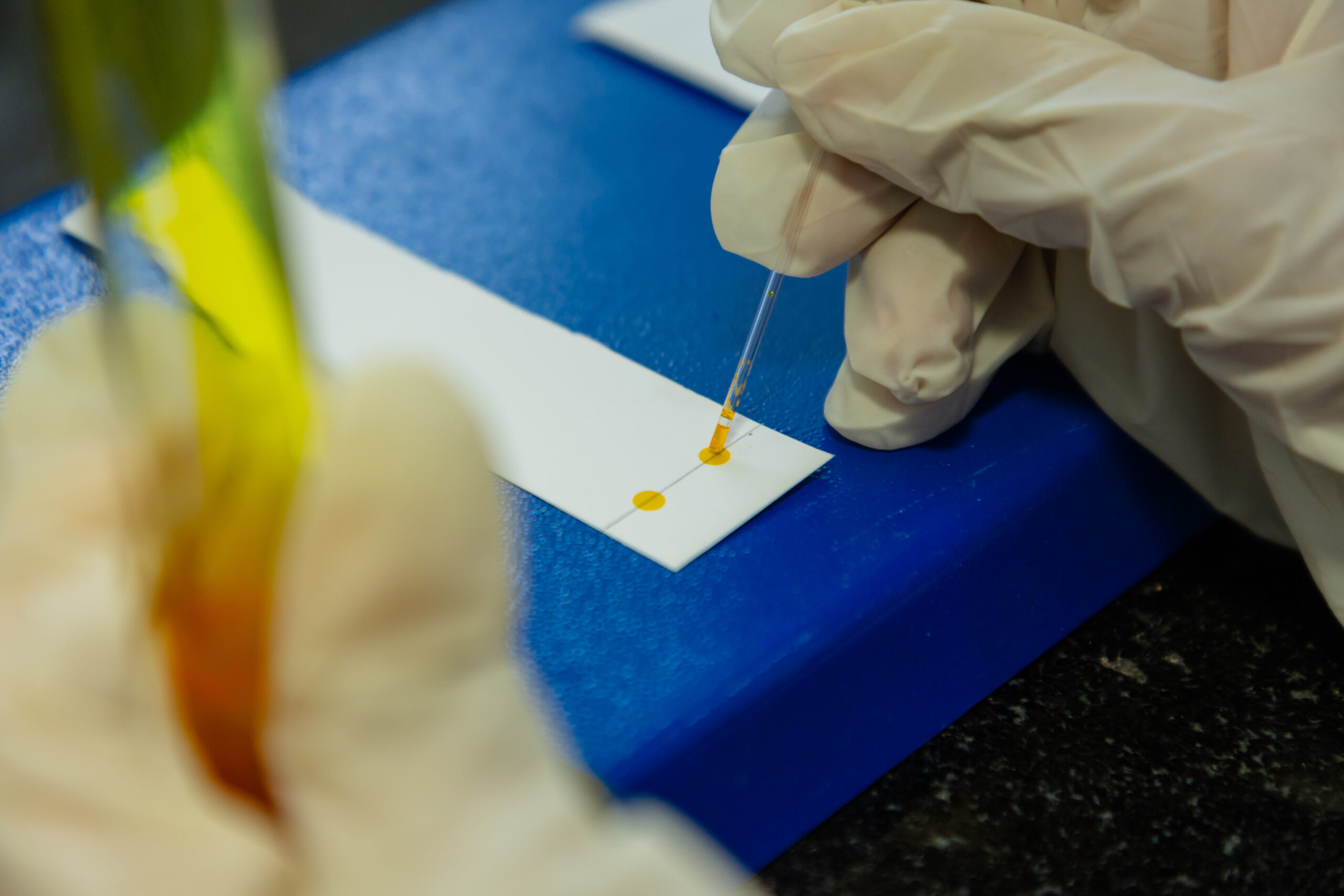

Our Quality Assurance and Quality Control (QA-QC) Lab is the backbone of our commitment to delivering premium-quality products. Equipped with cutting-edge analytical instruments like High-Performance Liquid Chromatography (HPLC), UV-Vis Spectrophotometers, and other advanced testing equipment, the lab ensures the highest standards of safety, efficacy, and consistency for every product we manufacture.

The lab plays a vital role in:

Our highly skilled team of chemists, and quality experts ensures that every product leaving our facility is safe, effective, and meets international quality standards, delivering unmatched trust and reliability to our customers.

Our liquid filling section utilizes precision technology to fill bottles with syrups, suspensions, and other liquid formulations. The automated system ensures consistent filling volumes and hygienic handling.

The liquid manufacturing section produces high-quality liquid formulations using state-of-the-art equipment, adhering to stringent quality standards to meet therapeutic needs.

This section focuses on accurately filling powders, granules, and capsules for nutraceutical products, ensuring proper sealing and maintaining the integrity of active ingredients.

Our packing section is designed to prepare finished products for distribution. Automated systems ensure proper labeling, boxing, and quality checks to meet regulatory and client standards.

The tablet coating section applies protective and functional coatings to tablets, improving their taste, appearance, and stability, while ensuring controlled release of active ingredients.

This section is equipped with high-speed compression machines to produce uniform and precise tablets, ensuring consistent dosing and therapeutic efficacy.

Our premises are designed to meet GMP (Good Manufacturing Practice) standards, featuring clean rooms, advanced equipment, and a safe working environment for all processes.